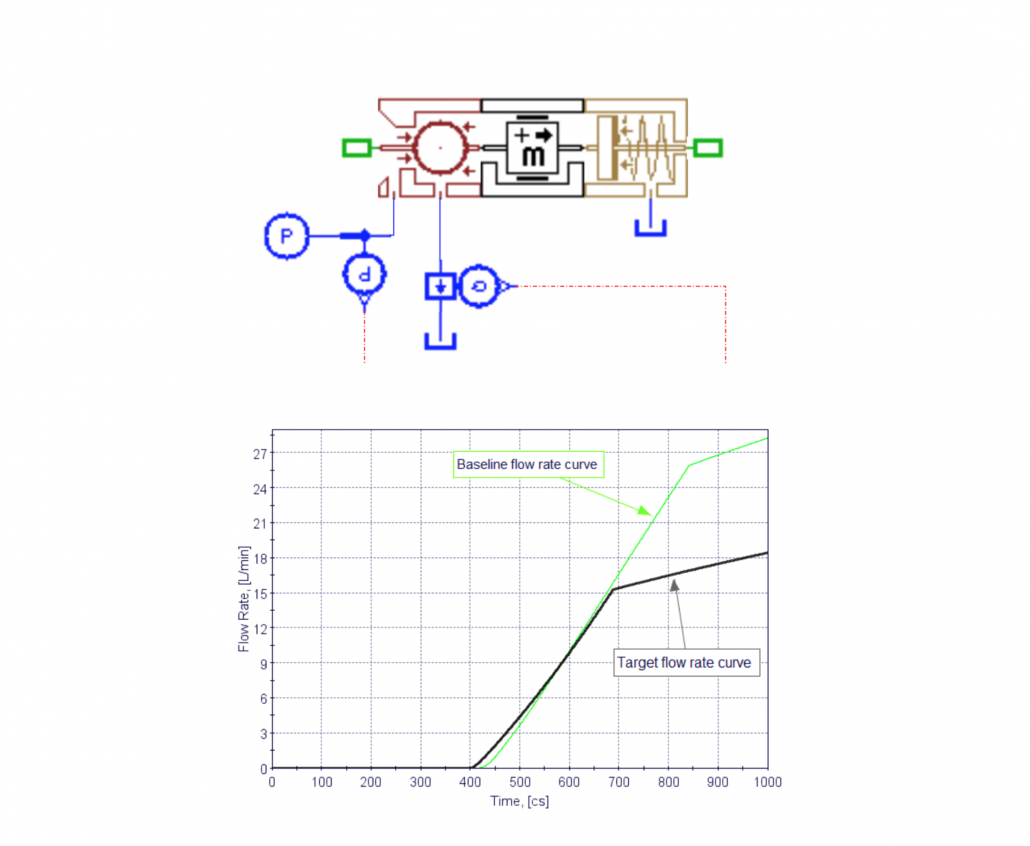

[vc_section css=”.vc_custom_1562154580550{padding-top: 40px !important;}”][vc_row][vc_column width=”1/2″][vc_gallery interval=”3″ images=”3551,3559,3453″ img_size=”500×300″][/vc_column][vc_column width=”1/2″][vc_custom_heading source=”post_title” font_container=”tag:h1|text_align:left” use_theme_fonts=”yes”][vc_column_text]This demo illustrates the connection between KIMEME and AMEsim to optimize the dimensions and characteristics of a check valve model in order to match a given pressure/flow characteristic.[/vc_column_text][vc_tta_accordion shape=”square” color=”white” active_section=”1″][vc_tta_section title=”DESIGN VARIABLES” tab_id=”1553179762281-9cff1c87-79d60e7b-660e3a81-3142″][vc_column_text]

Stroke: [1..10] mm

Spring Preload: [0..100] N

Stiffness: [0..100] N/mm

Seat diameter: [1..25] mm

Ball diameter: [1..30] mm

[/vc_column_text][/vc_tta_section][vc_tta_section title=”CONSTRAINTS” tab_id=”1553179762300-fff844f2-c11d0e7b-660e3a81-3142″][vc_column_text]Ball diameter must be greater than the seat diameter[/vc_column_text][/vc_tta_section][vc_tta_section title=”OBJECTIVES” tab_id=”1553180485145-d04b5cb9-574e0e7b-660e3a81-3142″][vc_column_text]Minimize error (ISE) betweed actual flow rate valve and desired target (respectively green and black)[/vc_column_text][/vc_tta_section][vc_tta_section title=”OPTIMIZATION ALGORITHM” tab_id=”1553180487891-c76fbf68-56fb0e7b-660e3a81-3142″][vc_column_text]Nelder-Mead method[/vc_column_text][/vc_tta_section][vc_tta_section title=”RUNS” tab_id=”1562154552316-67fbb75c-73a4″][vc_column_text]1500 evaluations, with parallel execution on 4 workstations using KIMEME Network. Execution time: 60 minutes.[/vc_column_text][/vc_tta_section][/vc_tta_accordion][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space height=”70px”][/vc_column][/vc_row][/vc_section]